Around March last year, the COVID-19 pandemic was becoming of increasing concern in the UK. I was living in my student house at university and trying to avoid unnecessarily catching anything. Students’ houses and especially bathrooms aren’t exactly known for being the cleanest of places, and so I decided that what our bathroom needed was an elbow tap!

Okay, an elbow tap probably wasn’t necessary but I had recently purchased a 3D printer (to help me finish my final year project) and I had not yet learnt that I didn’t need to be printing attachments and modifications for everything in my life… Frankly, I still need to learn that lesson.

So I took to Fusion 360 and started building! I looked at pictures of proper elbow taps on Google images and decided I didn’t need to be making mine that big, just big enough that I could use it easily.

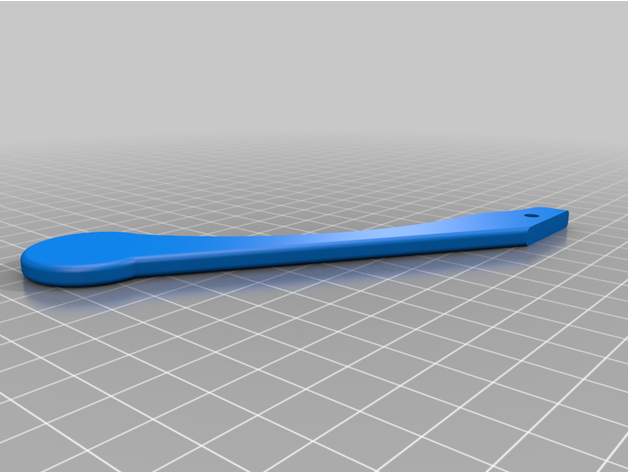

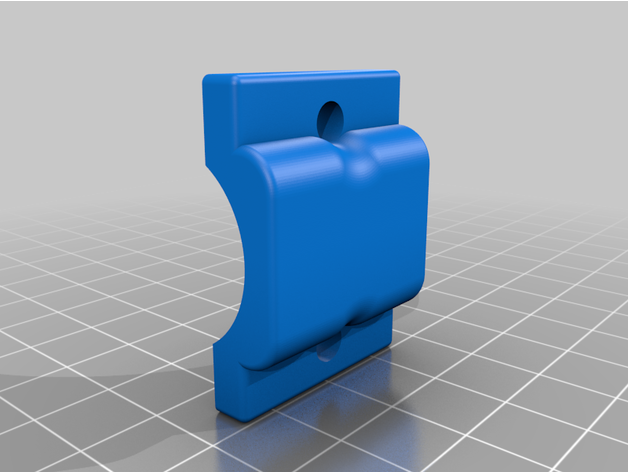

I eyeballed the measurements for the most part, to surprising success. I chose to split it into three parts (the arm and two halves of the clamp).

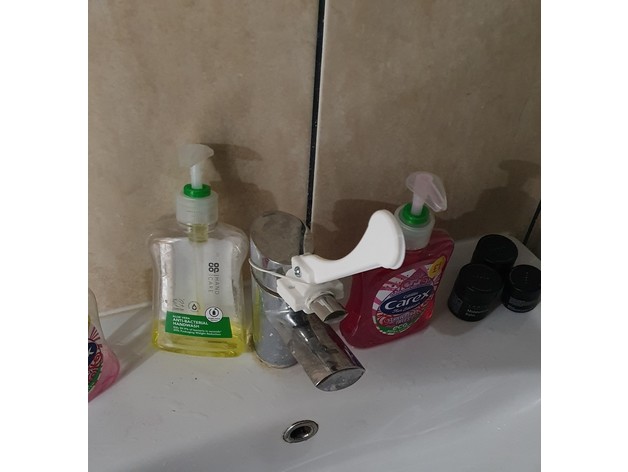

The parts were held together with M3 nuts and bolts, and fitted perfectly on the tap. Unfortunately, I’d failed to consider the fact that the existing tap handle was a perfectly smooth elliptic cylinder and so my attachment would be prone to slipping off. My solution to this was two elastic bands, one holding the attachment to the back of the tap and the other wrapped around the existing handle. This wasn’t exactly an elegant solution, but it worked and so it worked. Below is a picture of the elbow tap in use (along with 3 different bottles of soap for some reason).